One of the characteristics of a plant in crisis is that it once performed at a significantly higher level. Quantifying the current performance gap over a few months can quickly justify an immediate intervention.

In the early 1990s it seemed like every manufacturer and factory that embraced lean manufacturing practices only did so when faced with a crisis. Out of control inventory. Rework out the wazoo. Two-month order fulfillment cycle times. Foreign competitors eating their lunch on price.

This is no longer the case. In large part labor cost differences have been offset by other competitive factors. Manufacturers have made significant productivity improvements and those that could not compete globally ceased operations. Lean management practices and tools have penetrated every industry from manufacturing to healthcare to insurance. Few companies sustain their journey and capture the full benefits, but it no longer takes a crisis for business leaders to acknowledge the potential for long-term efficiency and performance gains.

That doesn’t mean that manufacturers no longer find themselves in a crisis. In any company there’s usually at least one manufacturing plant, even previous top performers, where performance has slipped a crisis is growing. The question is where, how much and why? Daily productivity levels may have fallen well below previous levels, rising scrap levels may be driving up costs, or order shipment dates may be slipping.

As we state in our recent management briefing about how to turn around facilities trending in the wrong direction: “A manufacturing plant occasionally becomes a case study for Murphy’s law. Anything that can go wrong, does go wrong.”

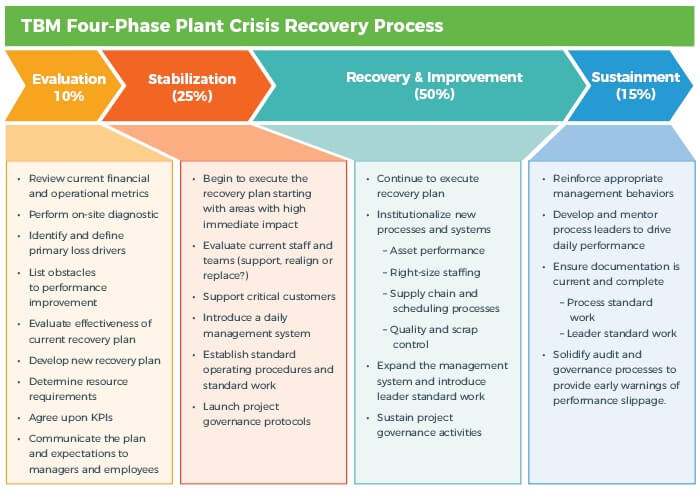

Once the crisis is clear, and the financial pain can no longer be tolerated, it’s time for an intervention. To turn around a plant in crisis quickly, it’s important to follow a disciplined process to identify the root causes, improve performance as quickly as possible, and then ensure that whatever triggered the crisis does not come back.

We break down plant turnaround process into four primary phases:

- Evaluation,

- Stabilisation

- Recovery and Improvement

- Sustainment

The turnaround starts with a review and evaluation of current performance. The second phase stops the immediate bleeding and supports critical customers while introducing a disciplined daily management system. The majority of the time is then spent on establishing new processes, systems and governance procedures.

Throughout the turnaround process optimal management behaviors are continuously reinforced to ensure the new performance levels will be sustained. We will explore these four phases in more detail in a subsequent blog post.

Are there any factories in your network on the verge or in the midst of a crisis? Is it time for an active intervention?

Even well-run companies occasionally have a manufacturing plant that jumps off the rails. Here’s an in-depth look at our four-step approach for getting a manufacturing plant back on track. Download our newest white paper on this topic: TBM Management Briefing: How to Quickly Turn Around an Underperforming Manufacturing Plant