Problem-solving in a factory requires a variety of real-world tools to get beyond surface-level symptoms and uncover root causes.

Over the years I’ve found that many everyday tools and measurement devices are surprisingly difficult to find at client sites. Sometimes they aren’t available at all.

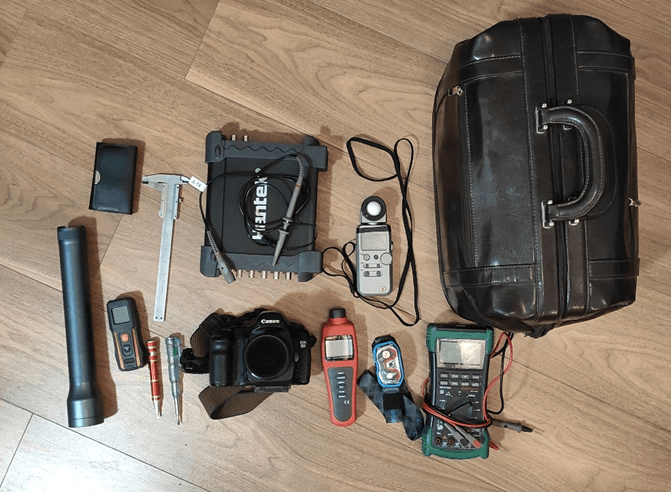

When diagnosing production line and equipment problems, here are some of the tools and instruments that I typically carry with me:

- Calipers

- Screwdrivers

- Multi-meter

- Tachometer

- Oscilloscope

- Laser distance meter

- Camera

- Light meter

- Torches (flash light)

At a basic level, when working with a team on a line or piece of equipment, you don’t want to have everyone standing around waiting while someone goes and looks for a torch, calipers or the right kind of screwdriver. I use the other tools pictured here less often but they can also save quite a bit of time.

I’ve pulled the laser distance meter out of my bag when working to setup new line layouts and arrange equipment. A tachometer is useful during TPM (total productive maintenance) events to calibrate a machine’s optimal working parameters. On several assignments, we have run into nonfunctional circuits where there’s no documentation and we had to use a multi-meter to troubleshoot entire control cabinets wire-by-wire.

I do not use an oscilloscope that frequently, but when I do, it has proven to be very powerful. On one project we needed to synchronize several actuators on an older production line that packed French fries into foil bags and then sealed the bags. We needed to coordinate the weight measurement system with each actuator to the millisecond. An oscilloscope was able to show which actuators were not in sync. Not only did we eliminate the quality issues, but the local maintenance team learned how to tune the machine properly vs. their old trial-and-error method.

When identifying opportunities for improvement, the light meter and camera are useful for capturing current state pictures before we move things around. When wrapping up a project, in addition to documenting the new workflow, it’s always a good practice to capture a few shots of the project team to recognize their efforts and celebrate success.

The light meter has also been useful when setting up optical quality-control systems. For example, in the French fry plant they had three optical systems designed to detect defects (black spots) on the product. Two of these machines had high scrap ratios and one did not. All the parameters of the machines were exactly the same. When we checked the lighting conditions using the light meter, we found that there was not enough ambient light on two of the lines for the system to function correctly.

Your maintenance and problem-solving teams should keep all of these tools handy and know how to use them.