A pharmaceutical manufacturer implements the TBM Management System, transforms the culture, reduces costs and creates room for growth.

Operationally speaking, market success can hide a lot of problems. The executive team at a rapidly-growing, global pharmaceutical manufacturer (which wishes to remain anonymous for this case study) did some hard calculations, and concluded that their production costs were as much as three times higher than the industry benchmark.

Unfortunately, much of those costs were linked to capital expenditures, and were therefore fixed. Still, they concluded that there were some significant opportunities for savings, especially as they continued to grow.

“We had a history of being very profitable, with very high margins, and protected products. That created a certain attitude and way of operating,” one executive explains.

When TBM Consulting Group began working with the company’s leadership team in 2008, they had settled on three primary mandates going forward:

- Continue to deliver high quality drugs to their patients.

- Grow the business but keep total head count constant in order to rein in costs.

- Create a culture of continuous improvement by everyone through the design and deployment of a consistent management system.

The third directive, which TBM worked with managers and employees at all levels to implement, would be the key to delivering the other two.

Like many entrepreneurial companies, this firm had grown by taking advantage of market opportunities as they arose without having a well-defined process for connecting the everyday activities of the business to high-level strategic goals. After the leadership team had established their three core objectives, in addition to becoming more efficient, the next question was, “How do we do it?”

Challenge: Production costs were above best-in-class benchmarks but management still wanted to create a more disciplined and directed organization while improving efficiency and keeping headcount steady for future growth.

The first step was the creation of a strategy deployment framework. For this the management team used the X-matrix tool to translate their objectives into annual goals for the site and for each value stream. They then determined the “breakthrough” projects that would be essential for realizing those goals, defined the relevant KPIs and assigned project ownership.

“Like many companies, they struggled to make the breakthrough projects a daily and weekly priority,” recalls Richard Holland, former Vice President and Managing Director of TBM Europe.

“So we helped them translate the breakthroughs into ‘100-day plans,’ which the leadership team now reviews on a weekly and monthly basis to see if sufficient progress is being made. The approach establishes clear accountability for achieving the long-term goals.”

Laying the conceptual groundwork for the new management system, TBM then trained the company’s executives and managers in the basics of lean and the most relevant problem-solving tools. Next, teams began to set up visual management tools, including SQDCP boards displaying daily and hourly safety, quality, delivery, cost and productivity metrics for each area. The boards now serve as focal points for daily performance reviews.

Solution: Over a 4-year period TBM helped roll out a comprehensive management system, starting with an initial assessment and intense leadership development. The system included strategy deployment, 100-day plans, monthly strategic reviews and daily performance reviews.

“We have a series of boards from the shop-floor level through area or functional boards to value-stream boards, culminating at the site leadership team board,” explains one manager. “Within that system, [status] meetings happen on a daily basis so that by 10:00 the site leadership team gets a full overview of the site’s performance in the last 24 hours, and what’s been done to resolve any issues and what needs to be done today to ensure today is a success.”

Combining daily performance with strategic activity, the boards also report progress toward 100-day plans and breakthrough objectives. Such practices have contributed to building a culture of open communication at all levels.

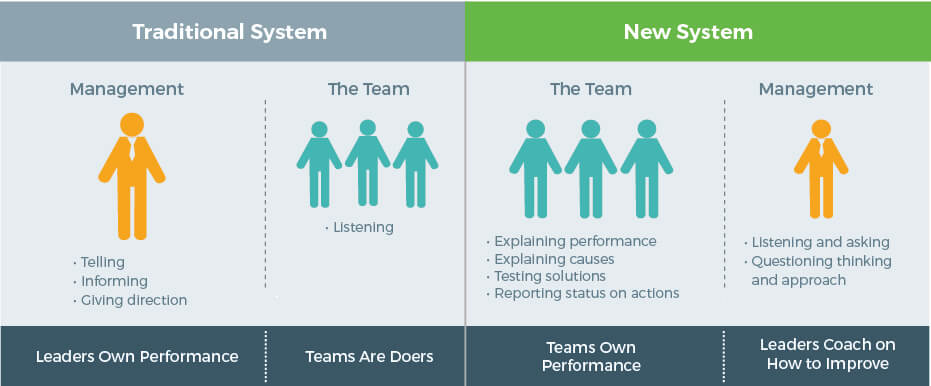

Within the TBM Management System, the role of managers is transformed from being the person in charge to being a support person and coach.

Today, the company’s culture is characterized by trust and collaborative problem solving. Trust is a result of the constant communication from the leadership team about where the organization is going. When it comes to making the targeted operational changes and improvements, that communication always emphasizes the need to build a sustainable business, not just reduce costs.

“It’s a fundamental role reversal,” Holland explains. “It transforms the job of the manager from being the person in charge who tells everyone what to do, to being a support person and coach. From being a talker to a listener. Instead of making all of the decisions, they ask questions and teach people to follow a solid thought process that leads to good decisions.” (See Figure 2)

The fact that the entire business is managed this way, not just the production areas, reinforces the management system and culture. The management approach is currently followed in finance, IT, logistics, procurement and human resources. HR, for example, presents daily reports on issues and solutions, such as the number of people needed and present for each shift, safety issues, and any discipline actions.

Results: Operating costs as a percentage of revenue were reduced by one third and were expected to drop even further when several new products came online. Making improvements and solving problems are now part of the company’s culture.

Today, reflecting the cumulative results of many productivity improvements, total employment at the site is up slightly, but output has grown 50 percent over the past four years. In the quality control area, for example, as the business has grown, total headcount has actually declined by 25 percent. Those people have moved to other areas of the business, and taken on the responsibility for other testing activity.

Most recently, process improvements in some administrative areas have freed up 60 people—over seven percent of the workforce—who will work on several major new products being readied for production at the facility. That additional output will improve the site’s cost position even further, which will continue the virtuous cycle of improvement and drive future business growth.