Catalogue retailer embraces enterprise-wide operational excellence to meet customer demand and high growth while reducing costs, improving order accuracy and avoiding capital expansion.

“The value chain contains the largest chunk of total costs and lead time… but is often the weakest link in a LeanSigma® transformation.”

Ninety-five percent of the United Kingdom’s population lives within 10 miles of an Argos store. Argos sells all types of merchandise, from toys and electronics to jewelry and furniture. Like most major retailers today, they offer a multi-channel approach, serving over 130 million customers a year in nearly 700 stores, as well as handling approximately four million orders either online or over the phone.

"Once you could sell speed or price," says Alistair Sercombe, Argos' Head of Operational Excellence. "Now customers routinely expect both. The performance of our retail, supply and distribution operations are all intertwined in that customer satisfaction equation." Argos started working with TBM with a focus on building Operational Excellence into its new National Distribution Center.

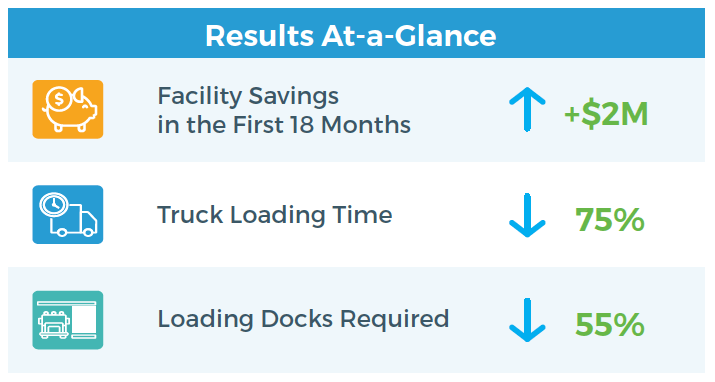

After saving more than £2 million at this facility in the first 18 months, Argos expanded its Lean Value Chain focus to other areas:

- Regional distribution centers: product returns, goods received and dispatch

- Home delivery distribution centers: small parts, put-away, returns and picking

- Retail stores: customer picking, returns and repairs

"We're in the early stages but a culture shift is definitely taking place," adds Alistair. "People are generating new ideas and building enthusiasm for involvement and improvement, not because it's a top management edict, but because they see the value."

One recent benefit: by cutting truck-loading time by 75% and reducing the number of loading docks required by 55%, Argos can now meet anticipated growth targets without new warehouse facilities.

Challenge: Meet anticipated growth without adding warehouses. Improve customer experience, minimise wait times, ensure pick accuracy, reduce excess inventory, minimise price variances and improve demand forecasting.

Solution: Pilot implementation plan in 4 facilities with value stream maps, lean assessment, and go-forward plan. Establish and train CI leaders, implement framework and structure for faster customer picking, returns and repairs.

The Lean Value Chain, the second ongoing phase of a LeanSigma transformation, eliminates excess pipeline inventory, long lead times, erratic demand, poor on-time delivery, price variances and limited visibility. By opening the entire chain's eyes to all the processes involved in getting their products to the customer--and then building excellence into all those areas--companies create the power to transform their competitive landscape.